(Isingeniso)

Emhlabeni wamapayipi namashubhu, kunezinhlobonhlobo zezindlela zokukhiqiza ezikhona, ngayinye inesethi yayo yezimpawu kanye nezicelo. Phakathi kwalokhu, i-Electric Resistance Welding (ERW) igqama njengendlela evelele yokukhiqiza amapayipi ensimbi. Kodwa liyini ngempela ipayipi le-ERW? Ukuqonda incazelo yepayipi le-ERW kubalulekile kunoma ubani ohileleke ezimbonini ezithembele ezinhlelweni zamapayipi eziqinile nezithembekile. Lokhu okuthunyelwe kwebhulogi kuzocubungula imininingwane yepayipi le-ERW, lichaza inqubo yalo yokukhiqiza, izinzuzo, izinhlelo zokusebenza, nokuthi kungani'sa ingxenye ebalulekile emikhakheni eyahlukene.

(Ichaza ipayipi le-ERW)

Ake siqale ngencazelo yepayipi le-ERW. I-ERW imele ukuthi i-Electric Resistance Welding. Ipayipi le-ERW wuhlobo lwepayipi lensimbi elakhiwe ngokushisela umthungo womugqa wensimbi noma ikhoyili ngobude kusetshenziswa ukumelana nogesi. Ngokungafani namapayipi angenamthungo, akhiwe ngocezu olulodwa lwensimbi, amapayipi e-ERW akhiwa ngokugoqa ishidi lensimbi eliyisicaba libe yisimo esiyisilinda abese eshisela imiphetho ndawonye.

(Inqubo Yokukhiqiza: Ukubhekisisa Kakhudlwana)

Inqubo yokukhiqiza ipayipi le-ERW ibandakanya izinyathelo ezimbalwa ezibalulekile:

Ukulungiselela Insimbi: Imichilo yensimbi yezinga eliphezulu noma amakhoyili akhethwa ngokusekelwe emibhalweni oyifunayo yepayipi.

Ukubumba: I-steel strip ikhiwa kancane kancane ibe yi-cylindrical shape kusetshenziswa uchungechunge lwamarola.

Ukushisela: Yilapho umlingo othi “Electric Resistance Welding” wenzeka khona. Imiphetho yesilinda esakhiwe ihlanganiswa, futhi amandla kagesi asezingeni eliphakeme adlula kuwo. Ukumelana nalokhu kwamanje kudala ukushisa okunamandla, okuncibilikisa imiphetho futhi kuhlanganiswe ndawonye, kwakheke ukushisela okuqinile, okude.

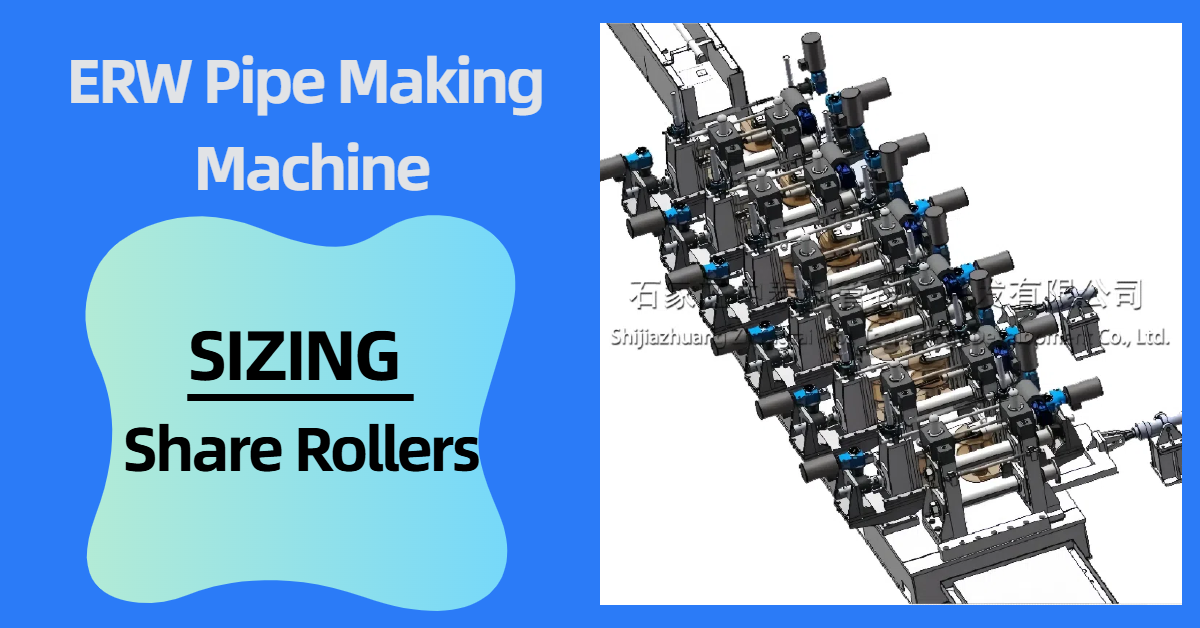

Ukulinganisa nokuBunjwa: Ngemva kokushisela, ipayipi lidlula kumarola okulinganisa ukuze kuzuzwe ububanzi obudingekayo kanye nokuma.

Ukusika Nokuqedwa: Ipayipi libe selisikwa libe ngobude obudingekayo futhi lidlulela ezinqubweni zokuqeda ezifana nokususa, ukuqondisa, nokuhlola.

(Izinzuzo ze-ERW Pipe)

Ipayipi le-ERW linikeza izinzuzo ezimbalwa ezenza kube ukukhetha okudumile ezinhlelweni eziningi:

Ukusebenza Kwezindleko: Ipayipi le-ERW ngokuvamile liyonga kakhulu ukukhiqiza uma liqhathaniswa nepayipi elingenamthungo, okulenza libe inketho evumelana nesabelomali.

Ukuqina Kwezindonga Ezingaguquki: Inqubo ye-ERW ivumela ukulawula okunembile phezu kogqinsi lwepayipi.

Amandla E-Weld Ahle Kakhulu: Amasu esimanje e-ERW akhiqiza amashisela aqine njengensimbi, noma aqine nakakhulu kunesisekelo.

I-Wide Range of Sizes: Ipayipi le-ERW lingakhiqizwa ezinhlobonhlobo zamadayamitha nobukhulu.

I-Versatility: Ifanele izinhlelo zokusebenza ezihlukahlukene, kusukela ekusekelweni kwesakhiwo kuye kwezokuthutha eziwuketshezi.

(Izicelo ze-ERW Pipe)

Ipayipi le-ERW lithola ukusetshenziswa okubanzi ezimbonini ezihlukene nasezisetshenziswayo:

Uwoyela Negesi: Okwamapayipi, ama-casings, namashubhu.

Ukwakha: Njengezingxenye zesakhiwo kumaphrojekthi wengqalasizinda.

Ezokuthutha Zamanzi: Okokuthutha amanzi ezindaweni zikamasipala nezimboni.

Izimoto: Okwamasistimu e-exhaust nezinye izingxenye.

Ukukhiqiza: Ezinqubweni ezehlukene zezimboni ezidinga ukuthuthwa kwamanzi noma igesi.

I-scaffolding: Isetshenziselwa izinhlelo eziqinile neziphephile zesikafula.

(ERW Pipe vs. Seamless Pipe)

Nakuba womabili amapayipi e-ERW namapayipi angenamthungo enza izinhloso ezifanayo, ahluke kakhulu enqubweni yawo yokukhiqiza nezici. Amapayipi angenamthungo anikeza amandla aphezulu futhi avame ukuthandwa ezinhlelweni zokucindezela okuphezulu. Nokho, amapayipi e-ERW ngokuvamile ayonga kakhulu futhi afanele uhla olubanzi lwezinhlelo zokusebenza lapho kungadingeki ukumelana nokucindezela okukhulu. Ukuqonda umehluko phakathi kwepayipi le-ERW vs ipayipi elingenamthungo kubalulekile lapho ukhetha into efanele yezidingo zakho ezithile.

(Indima Yezisetshenziswa Zokukhiqiza)

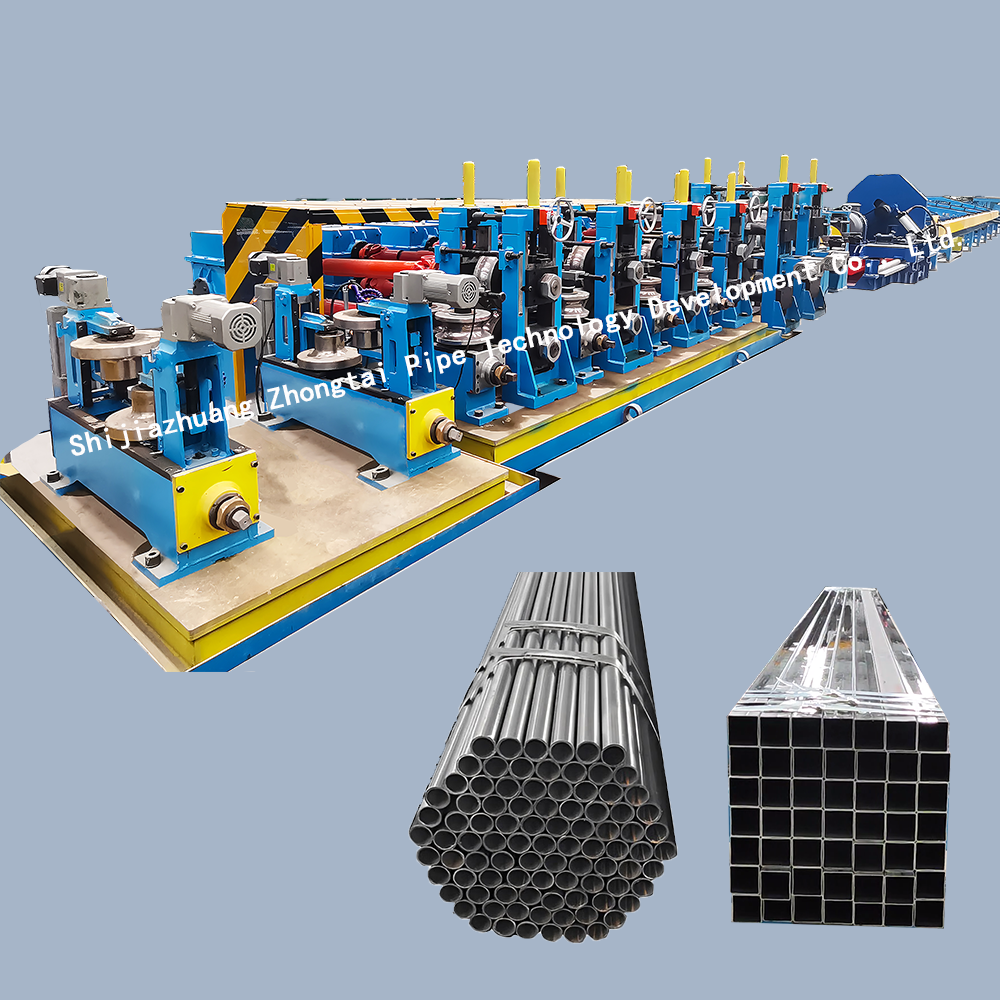

Ukukhiqiza ipayipi lekhwalithi ephezulu le-ERW kuncike kakhulu emishinini yokukhiqiza ethuthukisiwe. Lokhu kuhlanganisa:

Ama-Uncoiler kanye nama-Accumulators: Ukuphakela kahle amakhoyili ensimbi emgqeni wokukhiqiza.

Ama-Mill Forming: Ukubumba kancane kancane umucu wensimbi ube yi-cylindrical form.

Imishini Yokushisela: Inhliziyo yenqubo ye-ERW, ehlinzeka ngokushisela okunembe nokuthembekile.

AmaSizing Mills: Ukuqinisekisa ubukhulu bepayipi obunembile.

Imishini Yokusika: Ukusika ipayipi ngobude obufunayo.

Izisetshenziswa Zokuhlola Nokuhlola: Ukuqinisekisa ukuthi ipayipi lihlangabezana nezindinganiso zekhwalithi ezidingekayo.

Uma ubheka ukwenza ipayipi le-ERW, ukukhetha okokusebenza okufanele kubalulekile.

(Isiphetho)

Ukuqonda incazelo yepayipi le-ERW kanye nenqubo yokusungulwa kwalo kubalulekile kunoma ubani osebenza ngamapayipi ensimbi. Ipayipi le-ERW linikeza isixazululo esingabizi nesiguquguqukayo sezinhlelo eziningi ezahlukene. Ngokuqaphela izinzuzo zayo nokulinganiselwa kwayo, ungenza izinqumo ezinolwazi mayelana nokuthi uzokusebenzisa nini futhi kuphi lokhu kwaziswa okubalulekile. Ngaphezu kwalokho, ukukhetha imishini efanele yokukhiqiza kubalulekile ekukhiqizeni amapayipi e-ERW ahlangabezana namazinga emboni kanye nokulindelwe ngamakhasimende.

(Bizela Esenzweni)

Ingabe ufuna umshini wokukhiqiza ipayipi le-ERW elithembekile nelisebenza kahle? Xhumana nathi namuhla ukuze ufunde kabanzi mayelana nezixazululo zethu nokuthi singakusiza kanjani uthuthukise inqubo yakho yokukhiqiza!

Isikhathi sokuthumela: Feb-19-2025