Izimiso zokusebenza ziyahlukahluka ngokuya ngohlobo lwemishini yamapayipi ensimbi:

- **ERW Pipe Mills**:Sebenza ngokudlula amapheshana ensimbi ochungechungeni lwamarola awalolonge abe amashubhu angamacylindrical. Imisinga kagesi enemvamisa ephezulu bese isetshenziselwa ukushisa imiphetho yamapheshana, okwenza ama-weld njengoba amapheshana ecindezelwa ndawonye. Le ndlela iqinisekisa ukukhiqizwa okuphumelelayo kwamapayipi ashiselwe afanele ukusetshenziswa kwezimboni ezihlukahlukene.

- **Amapayipi Amapayipi Angenamthungo**:Qala ngokushisisa amabhilidi ensimbi ayi-cylindrical ezingeni lokushisa eliphezulu, okulandelwa ukubhoboza ukuze wenze amagobolondo angenalutho. Lawa magobolondo enza izinqubo zokugingqika kanye nokulinganisa ukuze akhiqize amapayipi angenamthungo anobukhulu nezakhiwo ezifanayo. Ukukhiqizwa kwamapayipi angenamthungo kuqinisekisa amandla aphezulu, ukuthembeka, nokumelana nokucindezela kwangaphakathi, okuwenza abalulekile ekusetshenzisweni okubalulekile.

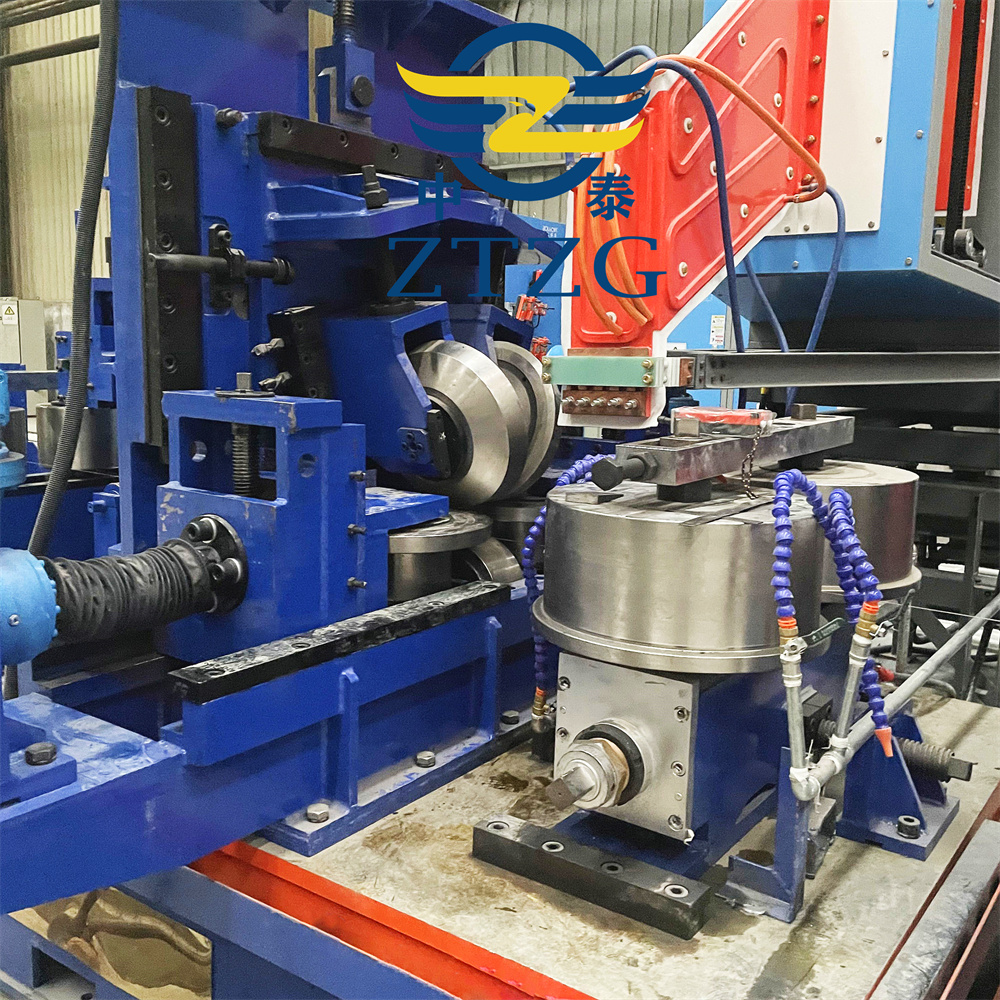

- **HF Welding Pipe Mills**:Sebenzisa ukufudumeza kwe-induction ye-high-frequency ukuze ushise imichilo yensimbi emaphethelweni awo. Amaphethelo ashisayo abe esecindezelwa ndawonye ngaphansi kwengcindezi ukuze enze ama-welds angenamthungo. I-HF yokushisela ihlinzeka ngamakhono okukhiqiza asebenza kahle ngokulawula okunembile phezu kwemingcele yokushisela, elungele ukukhiqiza amapayipi anekhwalithi nokusebenza okungaguquki.

- **Laser Welding Pipe Mills**:Sebenzisa imishayo ye-laser egxilile ukuze incibilike futhi ihlanganise imiphetho yensimbi noma amashubhu. Le ndlela yokushisela okungeyena othintana naye inikeza izinzuzo ezifana nezindawo ezincane ezithinteke ukushisa, ukulawula okunembile kwe-weld geometry, kanye nekhono lokushisela izinto ezingafani. Amapayipi ashiselwe nge-laser ahlangabezana nezidingo zekhwalithi eqinile futhi athandwa ezinhlelweni ezidinga ubuqotho obuphezulu bokushisela kanye nokukhanga kobuhle.

Lezi zinhlobo zemishini yamapayipi ensimbi zibonisa amakhono ahlukahlukene okukhiqiza enzelwe ukuhlangabezana nezidingo ezithile zemboni, ukuqinisekisa ukusebenza kahle kanye nekhwalithi ekukhiqizweni kwamapayipi.

Isikhathi sokuthumela: Jul-29-2024