Ukukhiqizwa okuphumelelayo kwamapayipi ekhwalithi ephezulu ka-Electric Resistance Welded (ERW) kuncike kakhulu ekuhlanganisweni okungenamthungo kwezingxenye ezibalulekile ezihlukahlukene ngaphakathi kwesigayo se-ERW tube.

Idatha ye-ERWi-tube Milliwucezu oluyinkimbinkimbi lomshini oklanyelwe ukuguqula amakhoyili ensimbi abe amapayipi aphelile. Isigaba ngasinye senqubo, kusukela ekulungiseni ikhoyili ukuya ekusikeni kwamapayipi, sibalulekile ekuqinisekiseni ubukhulu obunembayo, ubuqotho besakhiwo, kanye nokukhiqizwa okuphumelelayo. Lesi sihloko sizohlola izingxenye ezibalulekile ze-ERWi-tube Millfuthi bagqamise izindima zabo ezibalulekile ohlelweni lokukhiqiza amapayipi.

Uhambo luqala nge-uncoiler, enesibopho sokuqaqa ikhoyili yensimbi ngokushelela nangokuphephile. I-uncoiler eklanywe kahle iqinisekisa ukugeleza okuqhubekayo nokungaguquguquki kwezinto ku-Umshini wokugaya we-ERW, ukuvimbela ukujama nokuphazamiseka ekukhiqizeni. Lesi yisiqalo sohambo lokukhiqiza amapayipi, futhi ukuzinza kwawo kuba nomthelela kuyo yonke inqubo eya phansi komfula.

Okulandelayo, isigaba sokwenza i-Umshini wokugaya we-ERWkulapho umucu wensimbi oyisicaba kancane kancane ulolongwa ube yi-tubular form. Lesi sigaba esibalulekile sisebenzisa uchungechunge lwamarola ukugoba kancane kancane nokugoba umucu, kwakheka umumo oyindilinga odingekayo ngaphambi kwenqubo yokushisela. Ukuqondanisa okunembile kwerola nokulungiswa kubalulekile kulesi sigaba ukuze kuzuzwe amaphrofayili amapayipi angaguquki nanembile.

Inqubo yokwakha ku-Umshini wokugaya we-ERWkuthinta kakhulu izinga lepayipi lokugcina. Ukulandela inqubo yokwenza, isigaba sokushisela yilapho imiphetho ye-steel strip ebunjiwe ihlanganiswa ndawonye.

Isigayo seshubhu se-ERW sisebenzisa i-welding ye-high-frequency electric resistance, idale umthungo oqinile nohlala isikhathi eside. Ukunemba nokulawulwa kwenqubo yokushisela kubalulekile ukuze kuqinisekiswe ubuqotho besakhiwo sepayipi. Lesi sinyathelo siqinisekisa isibopho esihlala njalo phakathi kwemiphetho emibili yomugqa wensimbi.

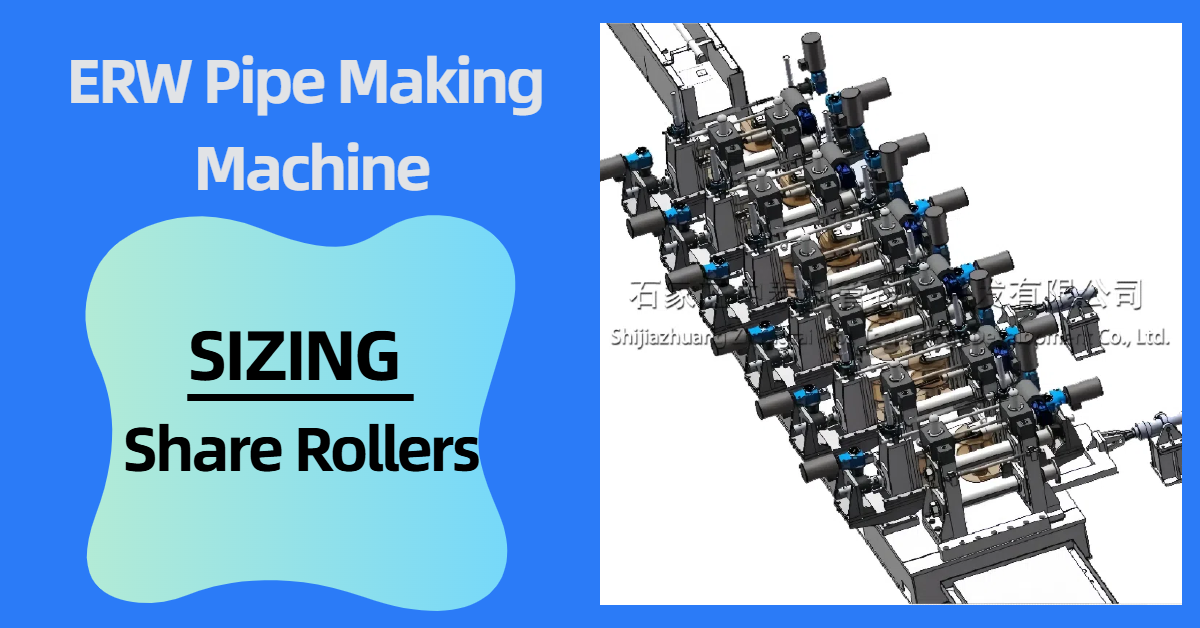

Ngemuva kwe-welding, isigaba sokulinganisa se-Umshini wokugaya we-ERWishuna kahle izilinganiso zamapayipi. Uchungechunge lwamarola lulinganisa kahle ipayipi ukuze libe ububanzi obufiswayo bokugcina nokuba yindilinga.

Ingxenye yokulinganisa ibalulekile ekuzuzeni ukubekezelelana okuqinile kanye nokuqinisekisa ukuthi ipayipi lihlangabezana namazinga embonini. Lesi sigaba sibalulekile kubukhulu bokugcina obunembile. Ingxenye yokuqondisa yesigayo se-tube isusa noma yikuphi ukugoba okusele noma amajika epayipi elishiselwe.

Iqinisekisa ukuthi umkhiqizo osuphelile uqonde ngokuphelele, okubalulekile ekuphathweni okulandelayo, ukugcinwa, kanye nokusetshenziswa. Lesi sigaba sisebenzisa ama-roller noma ezinye izindlela zokususa noma yikuphi ukuchezuka emgqeni oqondile, okwenza ipayipi eliphelele lezinqubo ezengeziwe.

Ekugcineni, isaha elisikiwe liyingxenye yokugcina yesigayo seshubhu ye-ERW, esisika ipayipi eliqhubekayo libe ngobude obucacisiwe. Isaha elisikiwe kufanele libe nembayo futhi lisebenze kahle ukuze kuzuzwe ubude obungaguquki ngenkathi kunciphisa ukumosheka kwezinto. Le nqubo yokusika iletha amapayipi okugcina aqediwe, alungele ukuthunyelwa.

Ingxenye ngayinye engaphakathi kwe-ERW tube mill idlala indima ebalulekile ekwenziweni okuphumelelayo nokunembayo kwamapayipi ashiselwe. Kusukela ekuqaqambeni kokuqala kuya ekusikeni kokugcina, isigaba ngasinye sibalulekile ekuzuzeni amapayipi anembile, asezingeni eliphezulu.

Ukuqonda lezi zingxenye nokuthi zisebenza kanjani kubalulekile ukuze kuthuthukiswe ukukhiqizwa kwamapayipi nokugcina ukusebenza kahle komshini wokugaya amashubhu we-ERW.

Lapho ukhetha umshini wokugaya we-ERW, ukucabangela ngokucophelela ukwakheka nokusebenza kwengxenye ngayinye kuyisihluthulelo sokuqinisekisa ukusebenza nempumelelo yesikhathi eside.

Isikhathi sokuthumela: Jun-28-2024