Ukuthuthuka kanye nezici eziyinhloko zobuchwepheshe bokubumba i-FFX

(1) Umshini wokwenza i-FFX ungakhiqiza amapayipi ashiselwe anezinga eliphakeme lensimbi, izindonga ezincanyana neziwugqinsi. Kusukela ukuguqulwa kwe-FFXumshini wokwenza ipayipiukwakha ubuchwepheshe ngokuyinhloko kusekelwe imiqulu enezingqimba, futhi imiqulu mpo esiteji sokwenza post-rough akudingeki ukusebenzisa rolls kwangaphakathi ukulawula deformation, isakhiwo imishini izici kokubili ukuthamba nokuqina, futhi kulula ukuzuza amandla aphezulu kanye rigidity okusezingeni eliphezulu futhi kungaba uzinzise Khiqiza izinga okusezingeni eliphezulu amapayipi ashiselwe ngenhla 210/10 mm, ~ 10 mm kanye nensimbi D P110.

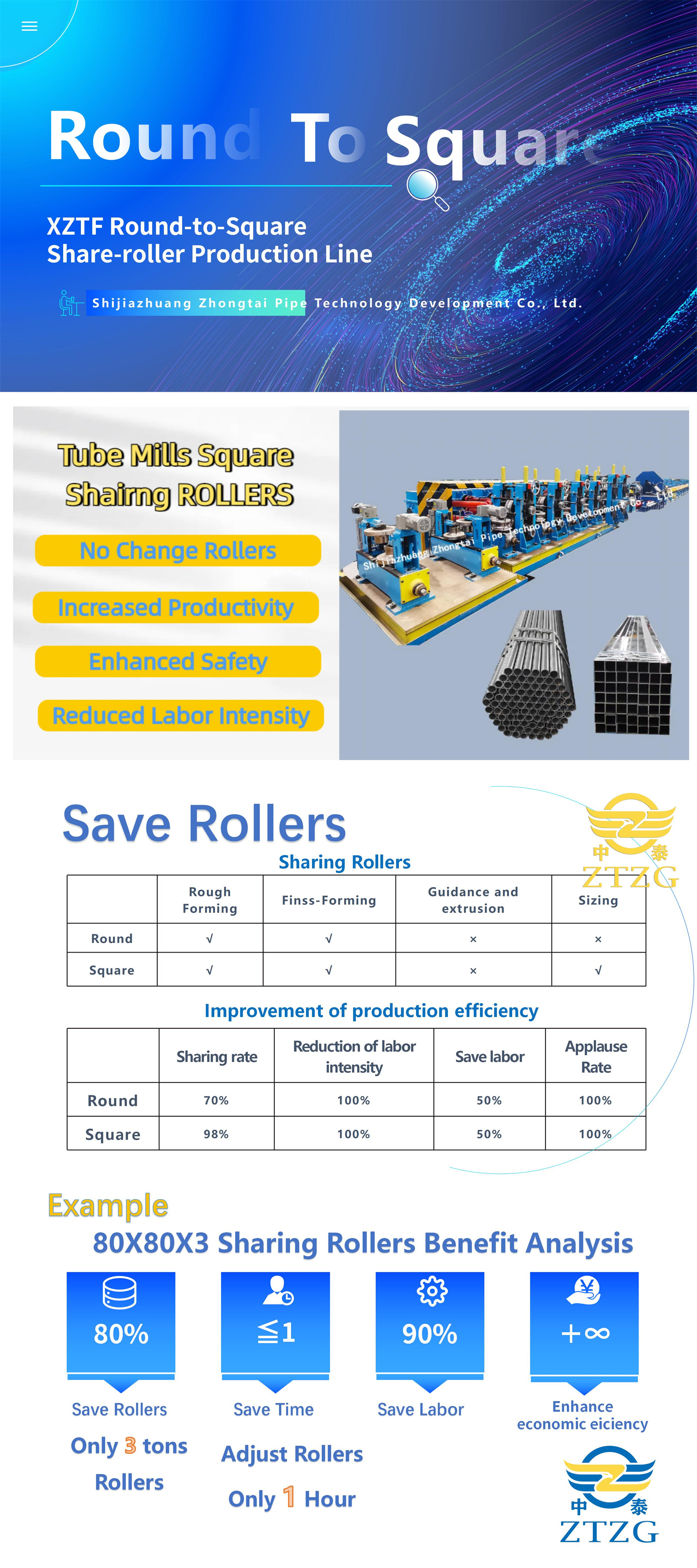

(2) Amaroli avundlile namaroli aqondile esigaba sokwenza i-FFX ku-aumshini wokwenza i-tubezabiwe ngokugcwele. Kubuchwepheshe bokwakha i-FFX, indlela yokugoba ye-involute kanye nendlela yokugoba i-roll-to-roll ihlanganiswa, ukuze amaroli avundlile namaroli aqondile kwabelwane ngawo ngokuphelele. Isibonelo, isigaba sesithathu sokwenza ipayipi le-ZTF roll in ai-tube Mill, ethuthukiswe yi-ZTZG, idinga kuphela ukwabelana ngeqoqo lamaroli ukuze kwenziwe amaholo. Lokhu kunciphisa izindleko zamarola futhi kwenza kube lula ukusetshenziswa nokuphathwa kwama-roll.

(3) Ukusatshalaliswa kwe-deformation kunengqondo, futhi inqubo yokubumba izinzile. Esigabeni sokwakheka okumahlaza kwe-ai-tube Mill, indlela enkulu yokuguqula ngokuyinhloko ithatha ama-rollers avundlile, ukuze i-curvature yohlangothi lwe-tube evulekile isondelene nepayipi elihlanganisiwe eliqediwe, futhi ukuguqulwa kokubunjwa okuhle kuncane. Lokhu kusabalaliswa okunengqondo kokuguquguquka kwenza ukubunjwa kuzinze futhi kunqobe ububi bokwakhiwa kwamarowu. Ingozi efihliwe yokukhubazeka kwamapayipi ashiselwe ibangelwa ukusatshalaliswa okungenangqondo kwe-deformation kubantu abadalaama-tube Mills.

(4) Indlela yokugoba eqhubekayo, esetshenziswa ku-ai-tube Mill, yamukelwa ukudala izimo ezinhle kakhulu zokushisela i-high-frequency welding. Ubuchwepheshe bokwakha i-FFX, njengoba busetshenziswe ku-aumshini wokwenza i-tube, yamukela indlela yokugoba eqhubekayo futhi isebenzisa ngokugcwele izici zokwakheka ezilandelanayo zamaroli avundlile namaroli aqondile. Lokhu kuqinisekisa ukuthi ayikho indawo efile yokuguqulwa engxenyeni ye-strip, futhi okubaluleke nakakhulu, inqoba ngokuphumelelayo ukuguqulwa okubangelwa izinguquko ekugqileni kwe-strip namandla. Ukunciphisa ukubuyiswa kwe-elastic kuthuthukisa ukunemba kokubumba nokuzinza ngaphakathi kwe-i-tube Mill. Ngemuva kokwakhiwa okunzima ku-i-tube Mill, unqenqema lwensimbi ye-strip lukhubazeke ngokuphelele ngokwepulasitiki, futhi ukugoba konqenqema lweshubhu evulekile kusondelene kakhulu neshubhu eliqediwe. I-deformation ngesikhathi sokwakheka kahle incane, iqinisekisa ukuthi ukuma kweshubhu evulekile ngemuva kokwakheka okungalungile kuyalondolozwa, okudala izimo ezilungile zokushisela imvamisa ephezulu ngaphakathii-tube Mill.

(5) Ithuthukisa ikhwalithi yepayipi elishiselwe elikhiqizwe yi-i-tube Mill. Uma kuqhathaniswa nobuchwepheshe bokwenza ama-roll, ubuchwepheshe bokwenza i-FFX, obuqaliswe ku-aumshini wokwenza i-tube, iphinde ithuthukise ikhwalithi yepayipi elishiselwe kulezi zici ezimbili ezilandelayo: Okokuqala, emva kokwakheka okungalungile ngaphakathi i-tube Mill, njengoba ukugoba konqenqema lwethubhu evulekile kusondelene kakhulu nomzimba wepayipi oqediwe, ukungahambi kahle kusuka kuma-rollers e-extrusion ngesikhathi sokuqeda kuyancishiswa, ngisho namapayipi ahlanganisiwe aqinile futhi aqinile. Ngemuva kokwenza kahle ngaphakathi kwe-i-tube Mill, izinhlangothi ezimbili zonqenqema lwe-strip zihambisana ngokuyisisekelo (hhayi ukuma kwe-V ephozithivu noma amalunga ezinqeni ahlanekezelwe omumo we-V). Ama-burrs afanayo akhiwa endaweni engaphakathi nangaphandle yepayipi elishiselwe, elivumela ukukhuhla kwe-burr. Ngesikhathi esifanayo, i-angle ye-welding enkulu emise okwe-V ingasetshenziswa phambi komshini wokushisela we-high-frequency, ukuvimbela ngokuphumelelayo ukukhubazeka kokushisela njengamabala ampunga. Okwesibili, ngenxa yendlela eqhubekayo yokwenza i-flange esetshenziswe ku-i-tube Millkanye nomklamo oyingqayizivele we-roll pass, noma iyiphi ingxenye yengxenye yensimbi ye-strip ingena kuphela ukuwohloka okukodwa ngesikhathi sesiteji sokwenza amaholo. Inguquko ye-deformation ixhumeke kahle, ivimbela noma iyiphi indawo eyodwa ukuthi ingakhubazeki ngokuphindaphindiwe, futhi ngaleyo ndlela, inciphise ukucwiliswa kwendawo ngenxa yokucindezela kwe-roll. Ngakho-ke, i-deformation ifana, ukucindezeleka kwangaphakathi kuphansi, futhi ikhwalithi yangaphakathi yonke yepayipi ehlanganisiwe ekhiqizwai-tube Millithuthukisiwe.

Ukufingqa, ubuchwepheshe bethu bokwenza amapayipi e-ZTF-IV ERW, buqaliswe ngaphakathii-tube Mill, ihlanganisa izinzuzo eziningi zokwenza umqulu wendabuko kanye nezindlela zokwenza i-flower roll, okubonisa intuthuko ephawulekayo. I-ZTZG isikhiqize imigqa eminingi yokukhiqiza amapayipi ashiselwe i-ZTF yamabhizinisi ahlukahlukene. Phakathi kwazo, i-Tangshan Wenfeng Qiyuan Steel yaklama futhi yakhiqiza umugqa wokukhiqiza ozenzakalelayo we-FFX wesizukulwane sesine ngaphakathi kwawo.i-tube Mill, ehlanganisa ukulawula ikhompuyutha, okubonisa ukuthi imiqondo emisha ye-ZTZG ingene esigabeni esisha. Ubuchwepheshe bethu be-ZTF(FFX) Flexible Forming, obusetshenziswa kuimishini yokwenza ama-tube, izoqhubeka nokuthuthuka futhi ithuthuke ngokusetshenziswa okuqhubekayo ngaphakathi kwei-tube Millimvelo.

Isikhathi sokuthumela: Feb-04-2023