Umshini Weshubhu Lensimbiφ377×16 ;ZTFIV;ZTZG

Incazelo

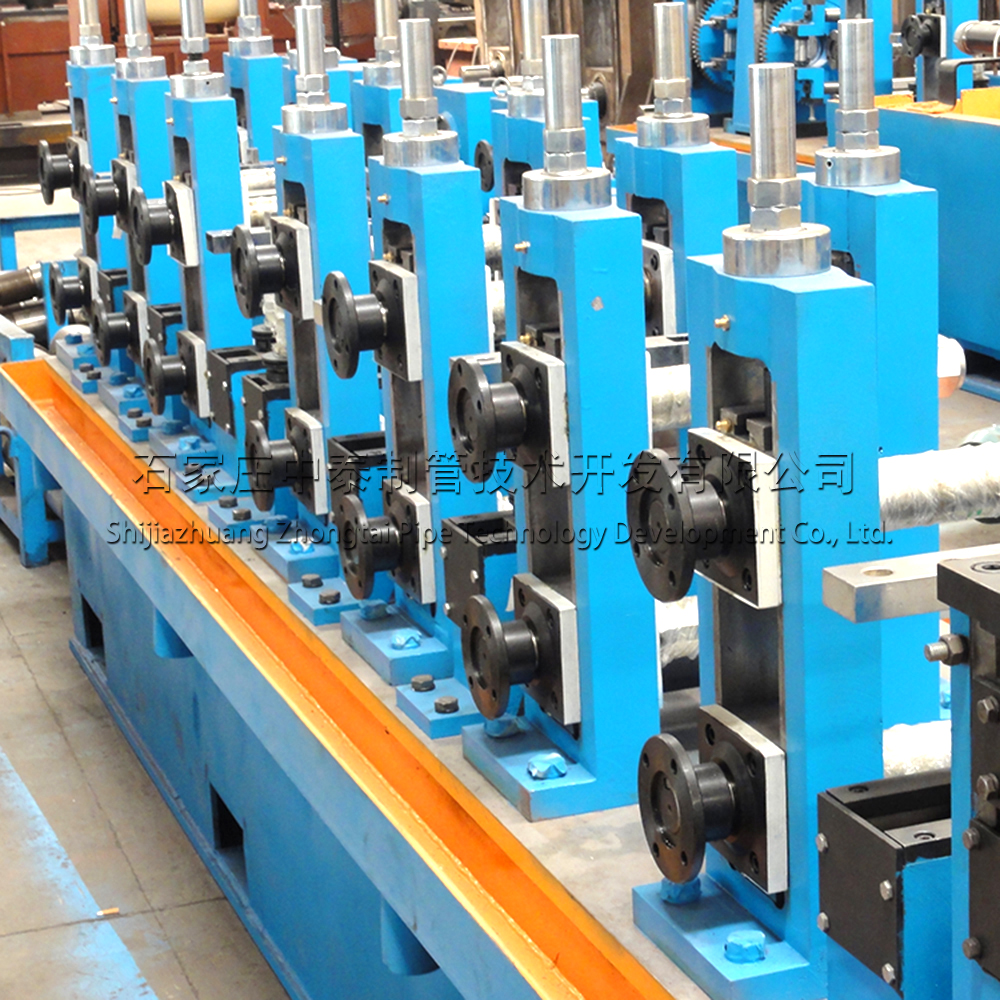

I-ERW tube mill ibizwa nangokuthi i-high-frequency longitudinal welded pipe line line. Izinto ezifanele amakhoyili emigqa agoqelwe ngokushisayo noma abandayo njengensimbi ye-carbon steel nensimbi enamandla amakhulu, njll.

I-strip steel ivulwa yi-uncoiler, bese ingena endaweni yokugcina i-accumulator ngemva kokudlula emshinini wokushisela izinqe ze-shear. Insimbi ye-strip ikhishwa ngama-rollers futhi ihlukaniswe izingxenye ezimbili: isigaba sokudiliza kanye nesigaba sokudlula esihle. Ngemva kwe-high-frequency induction induction kanye nengxenye yokulinganisa, khipha ubude bepayipi obudingekayo, unqanyulwe yisaha endizayo, bese ekugcineni upakishe bese upakisha ipayipi lensimbi. Lo mugqa wokukhiqiza uwumugqa wokukhiqiza ophelele wokushisela okuqhubekayo kwemicu yensimbi ibe amapayipi,ikakhulukazi yakhiwe uncoiler, shear & end welder, i-accumulator, umshini wokwakha nokulinganisa, HF welder, isaha endizayo, umshini wokupakisha nokupakisha.

Uma kunezinjongo ezikhethekile noma izidingo zamapayipi ensimbi, kuyadingeka ukwengeza imishini yokuhlola, njengomshini wokuhlola i-hydraulic, umshini wokukhipha imvamisa ophakathi nendawo, umshini wokubona amaphutha we-ultrasonic, njll.

Umugqa wokukhiqiza wepayipi oshiselwe imvamisa ephezulu usetshenziselwa ikakhulukazi ukukhiqizwa okuqhubekayo kwepayipi elihlanganisiwe lomthungo. Isebenzisa i-high-frequency induction welding, engakwazi ukukhiqiza ipayipi eliyindilinga kuphela kodwa futhi ipayipi eliyisikwele elihambisanayo namapayipi amise okukhethekile. Umshini wokushisela we-high-frequency pipe welding usetshenziselwa ikakhulukazi ukukhiqizwa kwamapayipi ensimbi ahlukahlukene, amapayipi okwakha, amapayipi esakhiwo, amapayipi amanzi, amapayipi kawoyela, amapayipi e-API, njalonjalo.

Tukugeleza kwezobuchwepheshe

Ukuskrolela phezulu→ Ukuqaqa → Ukugunda nokushisela→Isiqoqizi esivunguzayo→ Ukwakha → ukushisela i-HF yokungeniswa→Ukukhipha i-burr yangaphandle→Ukupholisa →Usayizi→ Isaha endizayo →Ithebula eliphumayo →Ukuhlola→Ukupakisha→Isitolo

Finqubo orming

| Ipayipi elijikelezayo | Cold roll ukwakha inqubo | Umklamo omuhle we-roller |

| Inqubo yokwenza i-ZTF | Yonga okungenani izindleko ze-roller ezingu-60% ngokulungiswa kokulawula ugesiFunda kabanzi | |

| Ishubhu yesikwele & elingunxande | Inqubo evamile yokuzungeza isikwele | Inqubo yokwenza ezinzile |

| Indilinga-kuya-yisikwele enekhanda lamaTurkey | Ikhwalithi yepayipi enhle | |

| Inqubo ye-direct square-to-square(DSS) | Isethi eyodwa ye-roller ingakhiqiza wonke amashubhu anokulawula ugesi kanye nokulungiswa okuzenzakalelayoFunda kabanzi |

Ulwazi Oluyisisekelo Lobuchwepheshe Lolayini Wokukhiqiza Amapayipi ashiselwe

| Umkhiqizo & Isivuno | Ipayipi elijikelezayo | 165mm-377mm Ubukhulu:4.0mm-14.0mm |

| Isikwele & Ishubhu elingunxande | 130mm×130mm -280mm×280mm Ubukhulu:4.0mm-14.0mm | |

| Ubude | 6m-12m Ubude bokubekezelela: ± 3mm | |

| Isivinini Sokukhiqiza | 35m/min | |

| Amandla Okukhiqiza | 120,000ton/ngonyaka | |

| Ukusetshenziswa | I-Mill ifakiwe Ikhono | 580 kw |

| Indawo Yomugqa | 145m(ubude) ×13m (ububanzi) | |

| Isisebenzi | 6-8 abasebenzi | |

| Impahla eluhlaza | Okubalulekile | Ikhoyili yensimbi ye-Carbon Q235B(ASTM GR·D,σs 230) |

| Ububanzi | 520mm-1190mm Ubukhulu:4.0mm-14.0mm | |

| I-ID yekhoyili | 580-760mm | |

| Ikhoyili OD | Ubukhulu2100mm | |

| Isisindo sekhoyili | 25.0t |

Inzuzo

Lapho ikhiqiza ipayipi eliyindilinga, ingasebenzisa indlela yokwenza i-ZTF

Lapho ikhiqiza ishubhu eliyisikwele & elingunxande, ingasebenzisa indlela ye-direct square-square (DSS)

Imikhiqizo:amapayipi esakhiwo sezakhiwo, amapayipi e-API, amashubhu onyawo lombhoshongo, ipayipi lensimbi lensimbi yemoto neminye imikhiqizo.

| I-ERW TUBE MILL LINE | |||||

| Imodeli | Ripayipi elizungezile mm | Isikweleipayipi mm | Ubukhulu mm | Ijubane lokusebenza m/min | |

| ERW20 | Ф8-Ф20 | 6x6-15×15 | 0.3-1.5 | 120 | Funda kabanzi |

| ERW32 | Ф10-Ф32 | 10×10-25×25 | 0.5-2.0 | 120 | |

| ERW50 | Ф20-Ф50 | 15×15-40×40 | 0.8-3.0 | 120 | |

| ERW76 | Ф32-Ф76 | 25×25-60×60 | 1.2-4.0 | 120 | |

| ERW89 | Ф42-Ф89 | 35×35-70×70 | 1.5-4.5 | 110 | |

| ERW114 | Ф48-Ф114 | 40×40-90×90 | 1.5-4.5 | 65 | |

| ERW140 | Ф60-Ф140 | 50×50-110×110 | 2.0-5.0 | 60 | |

| ERW165 | Ф76-Ф165 | 60×60-130×130 | 2.0-6.0 | 50 | |

| ERW219 | Ф89-Ф219 | 70×70-170×170 | 2.0-8.0 | 50 | |

| ERW273 | Ф114-Ф273 | 90×90-210×210 | 3.0-10.0 | 45 | |

| ERW325 | Ф140-Ф325 | 110×110-250×250 | 4.0-12.7 | 40 | |

| ERW377 | Ф165-Ф377 | 130×130-280×280 | 4.0-14.0 | 35 | |

| ERW406 | Ф219-Ф406 | 170×170-330×330 | 6.0-16.0 | 30 | |

| ERW508 | Ф273-Ф508 | 210×210-400×400 | 6.0-18.0 | 25 | Funda kabanzi |

| ERW660 | Ф325-Ф660 | 250×250-500×500 | 6.0-20.0 | 20 | Funda kabanzi |

| ERW720 | Ф355-Ф720 | 300×300-600×600 | 6.0-22.0 | 20 | Funda kabanzi |

| UMUGQA WOKUKHIQIZA OKUNGQINA WESTEEL | |||||

| Imodeli | Ripayipi elizungezile mm | Isikweleipayipi mm | Ubukhulu mm | Isivinini sokusebenza m/min | |

| SS25 | Ф6-Ф25 | 5×5-20×20 | 0.2-0.8 | 10 | Funda kabanzi |

| I-SS32 | Ф6-Ф32 | 5×5-25×25 | 0.2-1.0 | 10 | Funda kabanzi |

| I-SS51 | Ф9-Ф51 | 7×7-40×40 | 0.2-1.5 | 10 | Funda kabanzi |

| I-SS64 | Ф12-Ф64 | 10×10-50×50 | 0.3-2.0 | 10 | Funda kabanzi |

| SS76 | Ф25-Ф76 | 20×20-60×60 | 0.3-2.0 | 10 | Funda kabanzi |

| I-SS114 | Ф38-Ф114 | 30×30-90×90 | 0.4-2.5 | 10 | Funda kabanzi |

| I-SS168 | Ф76-Ф168 | 60×60-130×130 | 1.0-3.5 | 10 | Funda kabanzi |

| I-SS219 | Ф114-Ф219 | 90×90-170×170 | 1.0-4.0 | 10 | Funda kabanzi |

| I-SS325 | Ф219-Ф325 | 170×170-250×250 | 2.0-8.0 | 3 | Funda kabanzi |

| SS426 | Ф219-Ф426 | 170×170-330×330 | 3.0-10.0 | 3 | Funda kabanzi |

| I-SS508 | Ф273-Ф508 | 210×210-400×400 | 4.0-12.0 | 3 | Funda kabanzi |

| I-SS862 | Ф508-Ф862 | 400×400-600×600 | 6.0-16.0 | 2 | Funda kabanzi |